VMS Co renewed and MOSS subscription servers hugely reduce carbon emissions.

Deploying renewed video management and AI analytics servers for CCTV applications should be core to any company’s authentic carbon emissions strategy.

Manufacturing new Information and Communication Technology (ICT) equipment, such as the servers and client PC’s used in CCTV video management and AI analytics solutions, accounts for an estimated 4% of global carbon emissions. It is surpassed only by a few major industry sectors like electricity generation, heating, transportation, manufacturing, and construction. This article aims to make a compelling case for renewing ICT equipment, wherever possible. It considers cost savings; the reduction in carbon emissions; and gives assurance that renewed, professional ICT equipment is hugely reliable, with little increased risk of failure.

Renewing ICT equipment is one of the most effective ways for companies to lower their carbon footprint. Avoiding new equipment manufacture in this way directly reduces associated carbon emissions. This must be core to any company’s authentic, carbon emissions strategy, as recycling and carbon offsetting are simply not enough.

Video Management Servers Co. (VMS Co) has two product ranges based on renewed ICT equipment, along with its brand-new ranges. The company has a proven history of selling servers for video management and analytics applications, operating with a wide range of VMS and analytics software, and has successful deployments in prisons, airports, ports, power stations, industrial sites, public space, MOD, retail, shopping malls and more. VMS Co. is not a newcomer to the market.

VMS Co’s renewed ranges are MOSS™ (Managed On-Site Servers); a subscription service where VMS Co. owns, manages, maintains, and warranties the servers, installed at the customer's location, operating like an on-site data centre. The second is a renewed server range available to buy outright. Both MOSS™ and the renewed server ranges come with up to 7-years, next-business-day warranties and field engineer support. The renewed servers generally cost about half of the new server’s price, for an equivalent specification. The payback period for the MOSS™ maintenance subscriptions is around 36 months. MOSS™ is also categorised as an operational expenditure and aligns well with video management software rental options now prevalent in the industry.

Embodied carbon and the waste hierarchy

Approximately 80% of ICT equipment’s lifetime carbon emissions occur during its manufacture, not from its use. This is known as "embodied carbon", and includes raw material extraction, component production, and assembly. All often involve long, global supply chains, such as mining in one country, assembly in another, and shipping worldwide. The renewal of ICT equipment as a whole, or the components and boards within it, reduces the environmental impact of embodied carbon emissions compared to purchasing new items. The waste hierarchy for cutting carbon emissions ranks the priority as follows:

reduce > reuse > refurbish > recycle > dispose

VMS Co’s MOSS™ and renewed servers firmly target the ‘reduce > reuse > refurbish’ part of this hierarchy, where ‘embodied carbon’ emissions reduction has the greatest impact. This delays the need for recycling and reduces disposal pressure on waste systems and landfills.

Recycling

Recycling can offset about 2–3% of embodied carbon emissions. Carbon offsetting, which involves supporting nature-based or renewable projects to offset emissions, also contributes to reductions. However, this approach offsets but does not directly address or tackle the root cause of the problem.

Recycling ICT equipment recovers limited materials, with less than 20% of rare earth metals like neodymium, cobalt, and palladium efficiently retrieved. These metals are hard to recycle and destructive to mine. Reusing and renewing ICT equipment helps conserve resources and reduces the need for new extraction.

Assurance

The lifespan of ICT equipment depends on critical parts within the server, like batteries, HDDs, SSDs, and cooling systems, not the entire product. Replacing these key parts, along with cleaning and reusing CPU/GPU boards and chassis, allows servers to perform like new. VMS Co monitors component and board longevity in the field and selects known reliable parts for reuse. This can sometimes prove to be the better choice over new parts when targeting longevity, as they are proven to last.

VMS Co recognizes that customers need assurance that renewed servers are of no greater reliability risk when deployed in CCTV applications. To address this, VMS Co. provides up to 7-years, next-business-day warranties and field engineer support for its renewed servers, ensuring reliability and continuity on site. These are levels of support and warranty that surpass the standard warranties offered by most new, branded server manufacturers.

Product Longevity - The ‘Bathtub Curve’

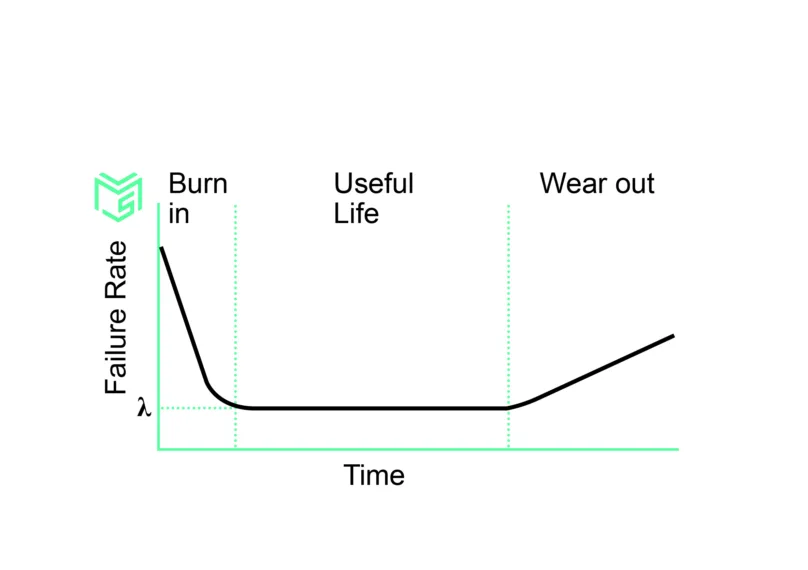

VMS Co. can offer long warranties because ICT equipment failure rates are not linear, but more typically follow a "bathtub curve" failure rate. This is where there are initial high failures, followed by stable reliable performance for many years, before a gradual increase in failures as the equipment ages.

The stages of the bathtub curve are:

- Burn-in: where the stress during first power cycles reveals hidden weaknesses, such as from manufacturing defects, assembly, handling, design flaws etc

- Useful life: the stable, low failure rate part of the product lifecycle, which can often be over 7 years.

- Wear-out: where failures increase again as equipment ages and components degrade.

VMS Co. uses equipment and parts that are in their optimal Useful Life stage, balancing reliability and cost. For CCTV applications, the ICT equipment does not need to be cutting-edge, but it does need to be dependable for many years. Our selection is focused on long-term reliability and maximum useful life.

The embodied carbon savings: new vs renewed

The embodied carbon in new verses renewed ICT equipment is as follows:

New: 300 kg CO₂e per Kg of ICT equipment.

Renewed: 50 kg CO₂e per Kg of ICT equipment, including the impact of cleaning, testing, replacing components, PSUs and HDDS.

Example: What are the carbon emissions savings by using 1000Kg (1 tonne) of renewed ICT equipment (this is around 1000x laptops or 50x, 2U servers) instead of new?

Savings are 250,000 Kg CO₂e (250 tonnes), which is the equivalent to:

- Driving a petrol car approximately 1 million km

- Charging around 30 million smartphones

- Avoiding 150 transatlantic flights

- Offsetting the annual emissions of 25 people (global average)

Reusing and renewing Information and Communication Technology (ICT) equipment offers both environmental and economic advantages. Companies developing a strategy to reduce their embodied carbon emissions footprint may find this approach relevant, particularly since performance and reliability need not be compromised, as a result of targeting the useful life of parts with known longevity.

The government is considering a carbon offset policy for renewal due to the significant emissions benefits that can be realised. However, changing perceptions about refurbished and renewed equipment remains a challenge, which we hope to address with our MOSS™ and renewed ranges, with their extensive warranties and field-engineer support.

Video Management Servers Co. - Making VMS and analytics simple, affordable, and sustainable.